Powder metallurgy knowledge

Factors affecting the price assessment of powder metallurgy products

Customized prices for powder metallurgical products are evaluated based on product requirements, materials, precision, and structural complexity. The volume of purchases is also a factor in the impact assessment.

The accuracy of powder metallurgy is also related to the price of powder metallurgy. Some customers think that the higher the accuracy requirement, the better. This is theoretically correct. However, in actual production, many times the precision of powder metallurgy products requires several wires, the materials used in the molds, and the control of the process have to change, and the cost has to rise a lot, or even double. Therefore, we will consider the cost when evaluating each drawing. According to the customer's use, we should give advice to the customer without affecting the use, and save the cost for the customer as much as possible.

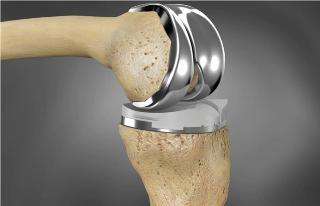

Regarding the influence of the complexity of the structure on the price of powder metallurgy, simple products such as straight shaft bushings, spherical bearings and other round products, because the product is simple, the mold production is simple, and the production does not require too much special control, so It will be cheaper. Gears and other structural parts, because they are irregular, molds require computer boring, engraving, electric welding, slow wire and other processes, so the mold cost will be slightly more expensive. Some chamfers, transverse holes, threads, multiple steps, blackening, heat treatment, and the need for electroplating cannot be achieved through the mold. After processing, they are all related to the price of powder metallurgy.