Magnetron sputtering coating target:

Metal sputter coating target, alloy sputter coating target, ceramic sputter coating target, boride ceramic sputtering target, carbide ceramic sputtering target, fluoride ceramic sputtering target, nitride ceramic sputtering Target, oxide ceramic target, selenide ceramic sputtering target, silicide ceramic sputtering target, sulfide ceramic sputtering target, germanide ceramic sputtering target, other ceramic targets, chromium-doped Silicon ceramic target (Cr-SiO), indium phosphide target (InP), lead arsenide target (PbAs), indium arsenide target (InAs).

Planar mammography

Product Name:Molybdenum target

Purity: 99.95%

Density: ≥10.2g/cm3

Size range:--- (can be customized according to customer needs)

Appearance: Under the microscope, the inner and outer surfaces of the tube exhibit a uniform metallic luster, without oxidation, hydrogenation discoloration, scratching, deformation, burrs, etc.

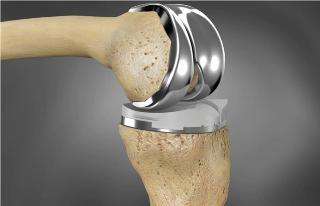

Uses: It is used to make heat-generating parts and heat-insulating parts for vacuum blast furnaces. It can be used in the chemical industry to make digester, heater, cooler, various utensils, etc., as well as in the fields of aviation, aerospace industry, medical equipment, etc. application.

The sputtering target is used for magnetron sputtering coating, which is a new type of physical vapor deposition (PVD) method.

An orthogonal magnetic field and an electric field are applied between the sputtered target (cathode) and the anode, and the required inert gas (usually Ar gas) is charged in the high vacuum chamber. Under the action of the electric field, the Ar gas is ionized to be positive. Ions and electrons, the target has a certain negative high voltage, the electrons emitted from the target are affected by the magnetic field and the ionization probability of the working gas increases, forming a high-density plasma near the cathode, and the Ar ion is in the Lorentz force. Under the action, it accelerates to the target surface and bombards the target surface at a high speed, so that the atoms sputtered on the target follow the momentum conversion principle and fly to the substrate to form a film with high kinetic energy off the target surface.

Sputter coating is mainly used in: flat panel display, coated glass industry (mainly including architectural glass, automotive glass, optical film glass, etc.), thin film solar energy, surface engineering (decoration & tools), (magnetic, optical) recording media, microelectronics , car lights, decorative coatings, etc.

The following sizes of molybdenum sputtering targets are available upon request:

Plate target: single weight: ≤200kg/pc, purity: ≥99.95%

Tube target: Length: ≤Φ165mmΧ1000mm, purity: ≥99.95%