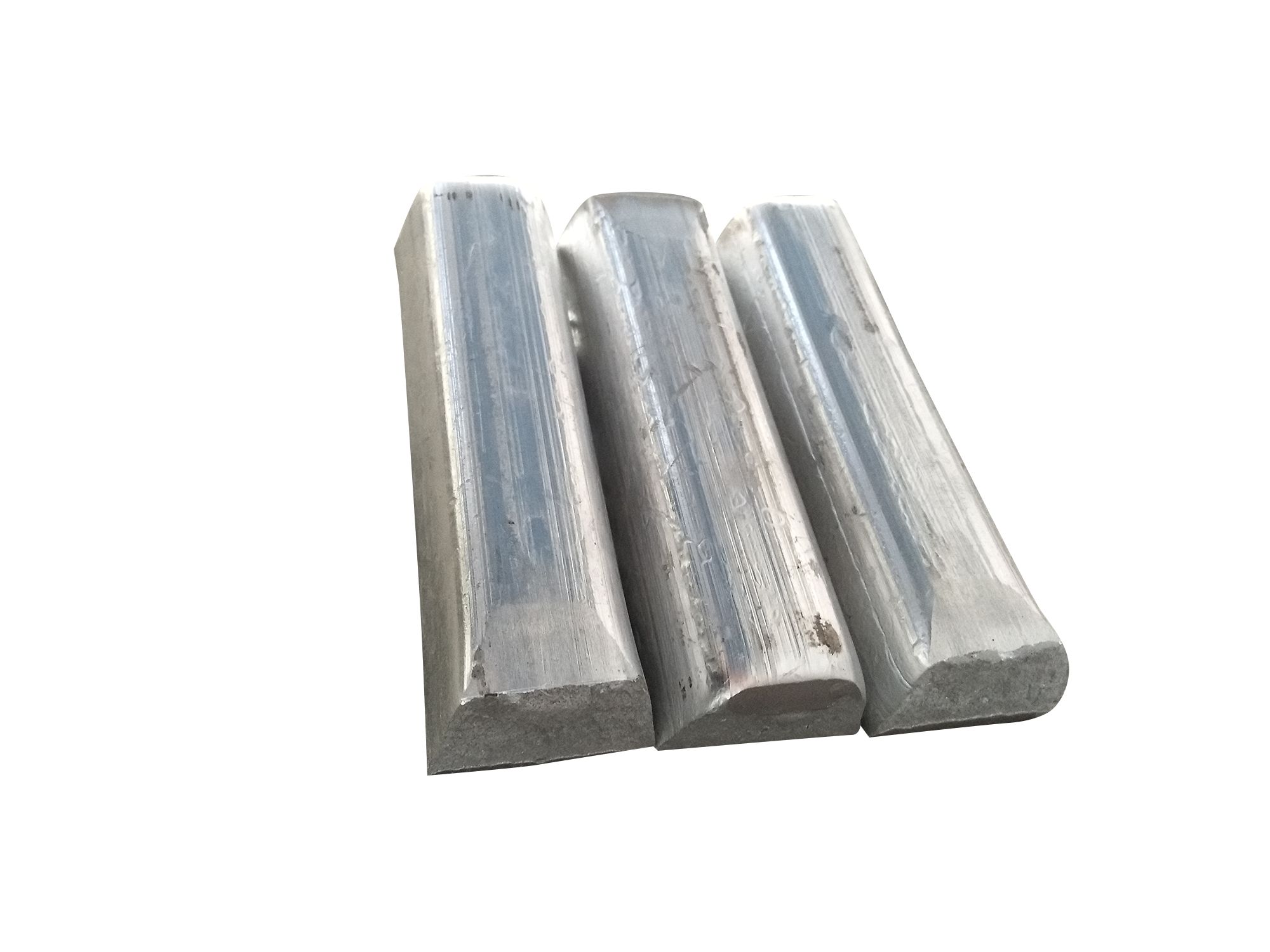

Aluminum titanium boron block AlTi5B1

characteristic:Containing 5% titanium and 1% boron, the balance is aluminum.

The internal components and metallographic structure are uniform, clean, non-segregation, segregation and inclusion.

Using high-quality pure aluminum and titanium boron compounds as raw materials, the process parameters are controlled accurately and the grain refining ability is expressed.

The refinement ability is long-lasting and the effect is strong.

It is extremely easy to use and has no pollution to aluminum alloy melt.

usage:

After the refining is completed, the aluminum slag is exhausted.

Adjust the temperature of the aluminum liquid to 700-740 ° C, preheat the aluminum titanium boron (rod) refiner at the furnace side.

1.0-1.5 kg per ton of 6063 aluminum alloy.

Disperse the input and stir for 5-6 minutes.

After standing for 15 minutes, it can be cast in water.

Use points: temperature, agitation, time.

Note: The addition method has a great influence on the grain size, and should be added twenty minutes before casting, which can exert the combined effect of Ti-B to a large extent.