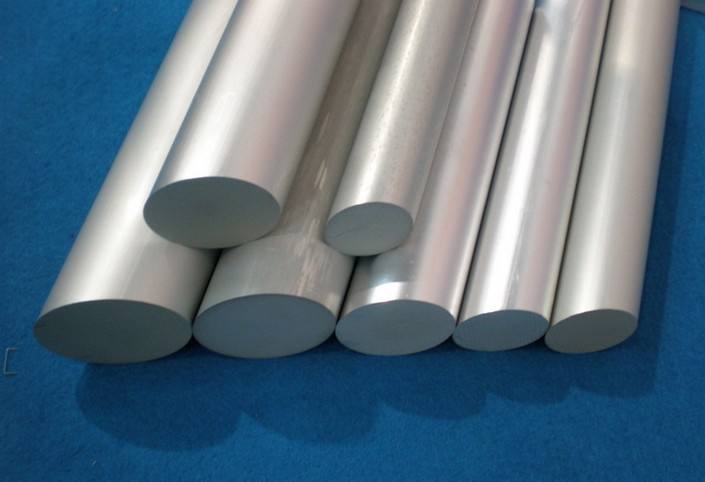

Product Name: Aluminum-copper intermediate alloy AlCu50 intermediate alloy

Characteristics:Suitable for all copper-containing aluminum alloy formulations.

Al50% Cu50% harmful impurities are less than 0.3%.

Proper use, the yield is stable between 98-100%.

The melting is rapid, and the phenomenon that copper is easily oxidized and discolored and refractory is eliminated.

Use method:

At 710 ° C, the temperature-adjusted aluminum liquid temperature is not lower than 730 ° C.

According to the composition standard of the alloy to be alloyed, the required amount can be calculated, and the aluminum-copper alloy can be divided by a saw blade. Not suitable for crushing.

Dry the aluminum slag and disperse the aluminum-copper alloy as much as possible into the aluminum liquid with a slight agitation.

Note: It should be avoided to throw it on the inner wall of the furnace, and it should not be concentrated in one place in the aluminum liquid.

use:

• The aluminum-copper intermediate alloy is mainly an additive type intermediate alloy. It acts like an additive and is directly melted in the aluminum liquid to adjust the copper content in the aluminum alloy to ensure the alloy properties.

• Packaging: woven seal, tray shipment